Construction and Building materials

The construction sector is one of the key sectors of the economy that consumes most of the natural resources and generates a significant amount of waste. Currently, the management of this waste in Thailand is inefficient while the construction waste continues to increase because of the growth in infrastructure construction. In this regards, the application of circular economy can help improve waste management of the construction, as well as increase the recycling, both in quantity and quality, in the future.

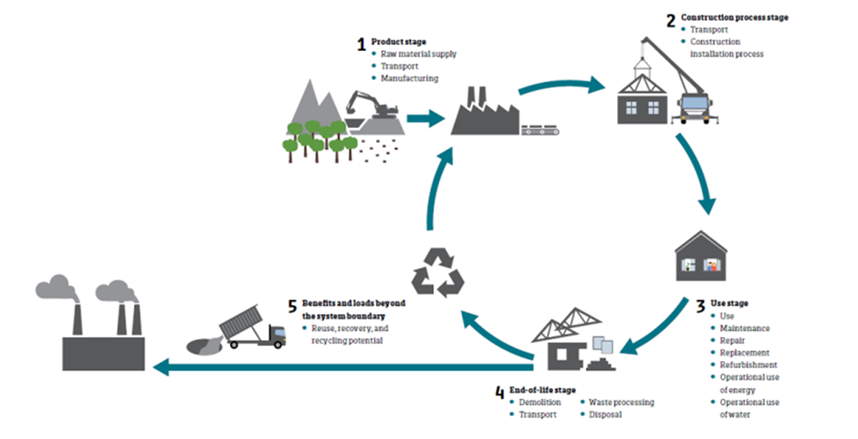

The challenges of creating sustainability in the construction industry are related to the growth of the country’s gross domestic product, the management of the resource, and the management of waste that occurred in the construction industry throughout the supply chain starting from the acquisition of raw materials used in construction, design and planning, construction process, waste management, and the reuse of the remaining materials with the highest efficiency as shown in figure 1. The concept of circular economy, is applied to the construction cycle in order to achieve the sustainability of the construction industry to help solve problems and create more efficient use of resources and energy, leading to the reduction of waste and environmental impact of the construction cycle.

Figure 1: The life cycle of building construction

(Source: European Insulation Manufacturing Association, 2017)

The construction industry consists of 2 main parts; the first part is building materials, and the second part is building construction. This industry is resource-intensive, involving the production of building materials such as structural materials (cement, steel, wood), and architectural materials (roofs, ceilings, tiles). For example, in the cement industry for construction as stated by the Department of Primary Industries and Mines in 2017 during the past 5 years (2012-2016), the limestone is required for production in the cement industry by an average of 70 million metric tons per year with an average growth of about 3-4 percent per year.

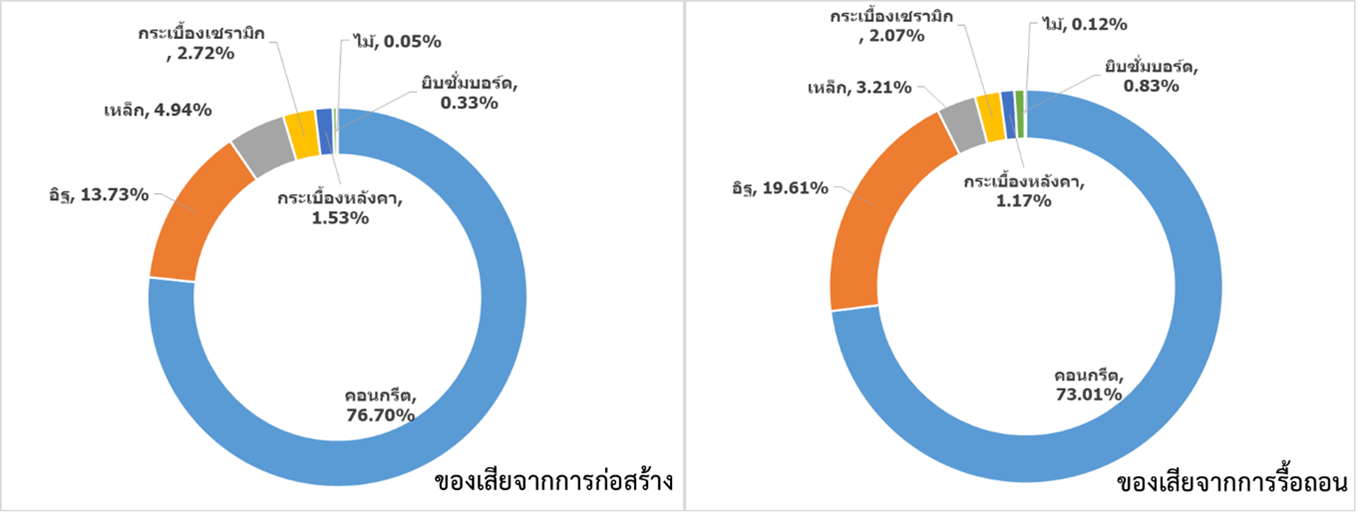

Apart from high resource utilization, construction and demolition (C&D) waste is accounted for 30-40% of waste in the landfills systems worldwide [1]. This group of waste usually consists of large or heavy materials, such as concrete and wood from buildings, asphalt from roads and roof components, gypsum (main drywall component), metal, bricks, glass, plastic, demolition building materials (doors, windows, internal connection equipment), as well as stumps, trees, and stones that caused by site preparation for Thailand’s construction as shown in Figure 2. Furthermore, C&D waste is also classified as Municipal Solid Waste (MSW). It was found that 70% of waste generated from construction and demolition were concrete, followed by brick, steel, ceramic, and tile.

Figure 2: Composition of construction and demolition waste

As for the amount of C&D waste in Thailand, especially in Bangkok area, since most of the building’s construction is done by demolishing or renovating the existing building area, thus the construction waste is generated at an average of 5.81 tons per 100 square meters of the building construction permit, equivalent to an average amount of waste at 3,173 tons per day. That is to say, at present, Thailand’s waste management is not efficiently managed.

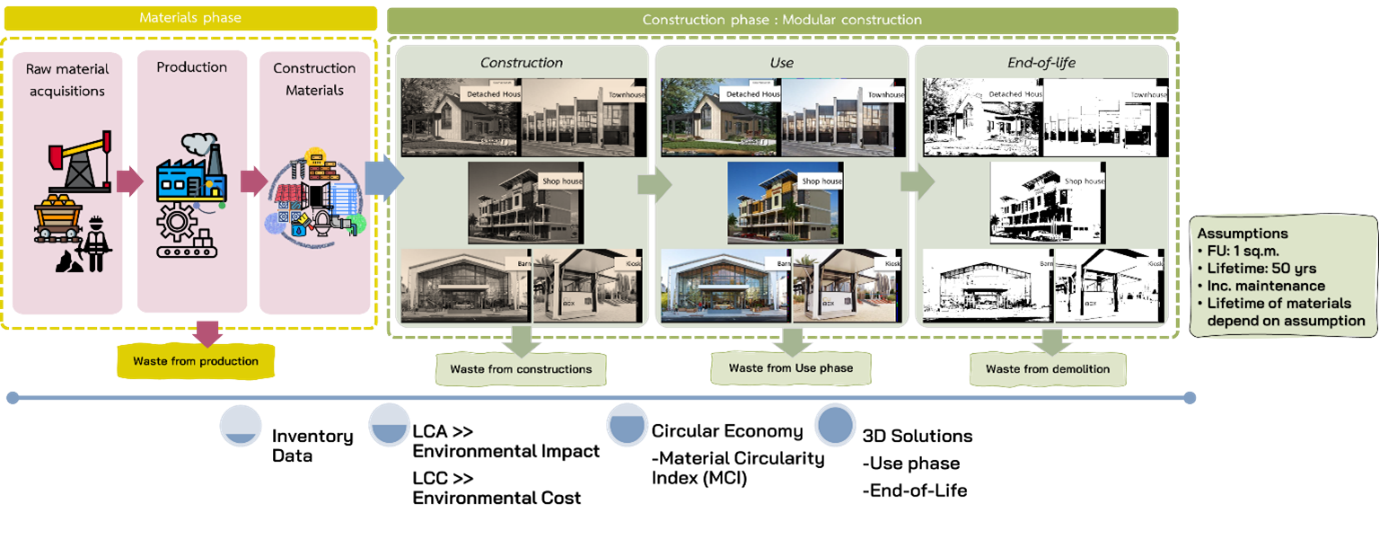

According to the mentioned problems, both the overuse of resources and the construction and demolition waste for the development of sustainable construction industry in Thailand should adopt the efficient “close-the-loop” guideline starting from the production of building materials, construction, and demolition, as well as increased management for the companies by designing, buying, and producing materials and energy for the construction. The application of circular economy, therefore, is used to design and create a building construction or refurbishment is required to take into account of environment and utilization of resources as shown in Figure 3.

Figure 3: Educational framework for developing a Digital Circular Solution to apply in the construction system from prefabricated steel structures throughout the life cycle.

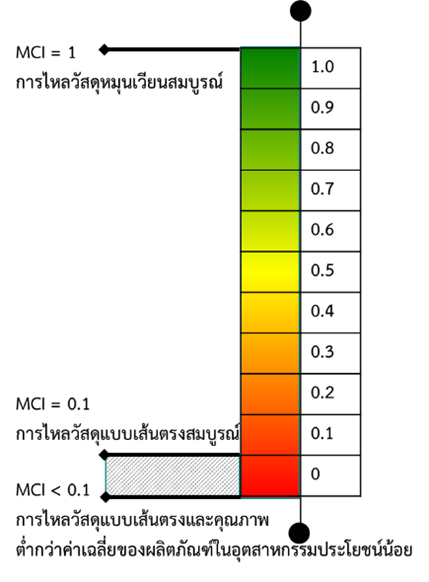

From the study framework, one of the key results is the Material Circularity Indicator (MCI), which can be used as a decision-making tool, as shown in Figure 4, for the product designer and buyer for choosing materials conforming to the circular economy concept with the effective utilization of resources. According to the figure, it can be seen that the MCI = 1 means that all materials used must come from reused or recycled materials (100% recycling efficiency), as well as no waste is generated during the production and when the product expires, it must be able to be reused without a loss (Zero waste to landfill). When the MCI = 0.1 means that the product has a completely linear flow and all materials used come from virgin materials with no reused or recycled waste. However, when MCI < 0.1 means that the product has inferior quality and properties than the average product in the industry, e.g. a shorter lifespan or an inferior quality or usability. On the contrary, if the MCI > 0.1 means that the product has high quality and properties compared to an average product in the industries.

Figure 4: The level of material circularity

It can be seen that this study is related to the Sustainable Development Goals (SDGs) aiming towards a circular economy throughout the life cycle of a creative environment. Thus, it is an ideal concept for sustainable development in the construction industry as shown in Figure 5.

Figure 5 : Circular economy system throughout the life cycle of a creative environment of the construction industry

The integrated information related to construction materials and buildings consists of an integrated data set of production factors, reuse of materials, and construction and demolition waste (CDW).

References

[1] Chen, Z., Li, Heng. and Wong, TC An application of bar-code system for reducing construction wastes. Automation in Construction. 11(2002) 521-533

[2] Circular Economy in Construction-Experiences from Finland. Ministry of Environment. (2019)

Further information, please contact:

Nongnuch Poolsawad

Researcher

02 564 6500 ext. 4857

nongnucp@mtec.or.th

th

th en

en